HEISHIN

Structure and Principles

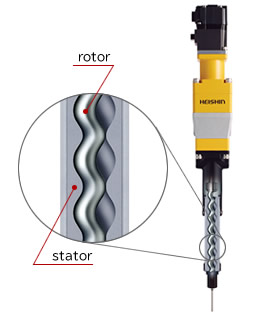

The basic structure of the Heishin Dispenser is a rotating positive displacement pump, the same as the Heishin® PC Pump.

The heart of the Heishin Dispenser is a rotor, which is equivalent to a male screw, and a stator, which is equivalent to a female screw. The rotor is made of metal and has a unique twisted angles, and its cross section is a perfect circle. The stator is made of elastic materials and its cross section is an oval.

When installing the rotor in the stator, a series of spiral cavities that are tightly sealed are created. When the motor rotates, fluids are injected in a reciprocal motion as the inside of the stator revolves; this is how the dispenser achieves non-pulsating constant discharge.

Applying

Heishin Dispenser enables a highly precise, non-pulsating application at a constant rate.

- No liquid accumulation and no need for cleaning after use

- Capable of even consistent application of materials by synchronizing robot speed

- Adjusting rotation speed of the servomotor can easily change application volume

- Capable of consistent application, not only in vertical, but also in horizontal or oblique positions

Filling

Offers highly precise discharge volume control and accurate filling at a constant rate.

- Can dispense any fluids of low to high viscosity

- No dripping keeps container and equipment clean

- Installed servomotor contributes to highly precise filling and a reduction in takt time

- Can be easily combined with conveyor movement

- Minimum filling volume is as little as 0.1 g

- Can correspond to small lot production of many products due to its easily disassembled and cleanable structure

products

A standard model[Type ND]

- Compact and light weight model.

- Excellent assembly reproducibility.

- Drastically reduces residual fluids.

- FIPG application on head covers, etc.

- Small volume application on precision substrates.

- Constant rate filling to syringes.

Heavy Duty Model[Type NDM]

- Capable of operation under extreme use.

- Offers reliable discharge of fluids that have nearly no liquidity.

- Used in various automotive production processes.

- Bead application on outer door panel of automobiles.

- Spot application on outer door panel of automobiles.

- Highly precise application of damping materials.

Quick & Clean Model

- An easy-to-clean design.

- Offers reduction in maintenance time.

- A safe and secure model that conforms to standards.

- Consistent filling of lipsticks to palettes.

- Can fill shampoo containers without creating froth.

Built-in Hopper Model[Type NVDL]

- Nearly no residual fluid.

- No shaft seal offers easy cleaning.

- Capable of multiple fillings.

- Capable of filling cosmetic lotions of various container types.

- Can be combined with conveyors to fill moisturizer bottles.

Two-component Mixture Unit

- The proportions of the compounds are easy to adjust because each volume of base compound and hardener dispensed can be easily changed.

- Capable of handling a wide range of viscosities of liquid, up to 500,000mPa·s.

- Capable of applying two compound mixture.

- Capable of filling two compound mixture that has wide gap in viscosity and mixing rate.

Controller

Controller designed for high-precisely Heishin Dispenser.

Accessaries

Accessaries bring out the Heishin Dispenser’s capabilities to the fullest.